Enhance Product Distribution

Key Action Area

Enhance Product Distribution

Action Area

Enhance Product Distribution

Summary

Transporting food from where it is produced to where it gets processed and/or ultimately sold and consumed is complicated under any circumstances, but the challenge increases with time-sensitive products, strict quality standards, and specific temperature requirements to maintain. While food loss and waste through distribution activities are comparatively low across the supply chain, delays or damages in the transportation process can lead to waste downstream.

"Enhancing product distribution" means maximizing freshness and selling time by harnessing the power of technology to create smart systems to efficiently move products. Solutions in this action area include technological tools, such as intelligent routing and sensors that aid in cold chain management, but these innovations must be situated within updated management procedures that prioritize remaining shelf life and intelligent routing practices that shorten transit times. These solutions lead to improved freshness and quality, so both suppliers and buyers have much to gain.

With a majority of product distribution solutions geared towards increasing the efficiency of internal operations, over 70% of the financial investment in this action area should come from Corporate Finance and Spending. The companies that adopt solutions should invest in building the necessary infrastructure and, at times, financing the products under development in order to implement and reap the benefits.

Key Indicators (Annual)

Best Practices

Interventions which are either not clearly definable as a specific solution, such as incremental improvement of existing common processes, or solutions that have already been implemented by a sufficiently large number of stakeholders such that there is little additional opportunity for them to address food waste that is still happening in the U.S. today.

Optimized Truck Packing, Loading & Unloading (e.g., Cross-Docking)

Use of best practices that maximize space, maintain air flow and appropriate temperatures levels for food safety, and minimize dwell time and unnecessary movement.

Cold Chain SOPs

Implementation of best practices for cold chain maintenance and waste prevention, as well as the education, training, and materials needed to ensure consistent use of practices across the industry.

Regular Maintenance on Refrigerated Trucks

Updates, checks, and calibrations on truck technologies and materials to ensure accurate temperature measurement of food during transportation and temporary holding in trucks, with consideration to the impact of fluctuating or improper temperatures on food quality and safety.

Cross-Docking

Logistics maneuver in which in-bound products are immediately unloaded and reloaded for appropriate out-bound distribution, thus minimizing handling and dwell time and maximizing a single coordinated step.

Levers

Financing

- Operational Changes Require Corporate Capital - Operational changes such as intelligent routing, temperature monitoring and decreased transit time will require corporations’ internal capital to purchase and implement these solutions, and change behaviors of employees through training and incentives.

- Private Investments Drive Effectiveness and Reduces Costs, Supporting Solution Adoption - Venture Capital and Corporate R&D drive greater effectiveness and decrease costs for distribution technologies and solutions, which encourages their adoption in both large and small organizations. We have already been seeing lower costs for environmentally friendly sensors, increasing accessibility for various temperature monitoring solutions. Additionally, as consolidation occurs in technology-enabled solution providers and winners emerge, Private Equity can help scale these solutions with growth capital.

- Public Funds Increase Accessibility and Support Societal Good - Impact-First Investors, Government, and Non-Government Organizations have a significant role to play in filling in the gaps not addressed by other capital types. Perceived risk is reduced by providing capital help organizations to run pilot programs to make distribution efforts more efficient – thereby giving these businesses the opportunity to understand the ROI before financing themselves.

Annual Investment Needed

Total

$1.1B

Public

Government Grants - $15M

Philanthropic

Non-Government Grants - $27.9M

Impact-First Investments - $57.6M

Private

Venture Capital - $105.4M

Private Equity - $105.4M

Corporate Finance & Spending - $794M

Policy

- Encourage Crop Preservation and Post-Harvest Loss Prevention Technologies – [Federal; Legislative and Regulatory] To increase support for innovations that reduce food loss, USDA could give preference to projects that address issues of crop preservation or post-harvest loss prevention in the Specialty Crop Research Initiative (SCRI) and/or other grant programs. This could be done directly by USDA or through the direction of Congress.

- Fund Spoilage-Inhibiting Technologies – [Federal; Legislative or Regulatory] Similar to the Specialty Crop Research Initiative (SCRI), there is a need for a funding mechanism that focuses exclusively on providing support for research and development of new technologies that demonstrate effectiveness in loss prevention of dairy, meat, poultry, and fish. To do this, Congress could create a program, possibly in the next Farm Bill.

Engagement

- Cold Chain Training and Incentives - Food businesses should emphasize cold chain management operating procedures in interactive employee training and waste reduction incentive programs to increase consistency in execution of proper food safety, handling, and preparation protocols.

- Cross-System Information Sharing through Technology - Retailers should collaborate with manufacturers and distributors to implement technologies that will drive additional transparency in end-to-end product supply chains, such as monitoring of pathogen testing, temperature, GPS, drops, or vibration tracking.

- Collaboration for Best Practices - Food businesses should share pre-competitive industry knowledge such as expertise, technological insights, and standardized best practices, as well as physical resources such as idle transportation and cold chain assets, which can result in a higher standard of industry efficiency.

- Diversify Market Partners - Manufacturers and distributors should build relationships with alternative market partners (e.g., secondary resale or matching programs) to build resiliency in product sales channels and identify partnerships for short notice sales.

Innovation

- Supply Chain Data Integration - Continued data integration into logistics is needed to improve supply chain visibility of freshness and temperature exposure, ultimately allowing for smarter product usage decisions according to shelf life.

- New Infrastructure Solutions - Creative infrastructure solutions, such as micro-fulfillment centers and convertible spaces, would help to minimize on-hand inventory and reduce last-mile time and costs.

- Processing and Handling Tech - Improved mechanized and automated processing capabilities across supply chains can optimize product handling.

- Coordinate Idle Assets - Optimized coordination systems and technologies will bolster relationships between food businesses to fully leverage idle cold storage and transportation assets, streamlining communications, and increasing access when needed.

Stakeholder Recommendations:

Here's How You Can Reduce Food Waste

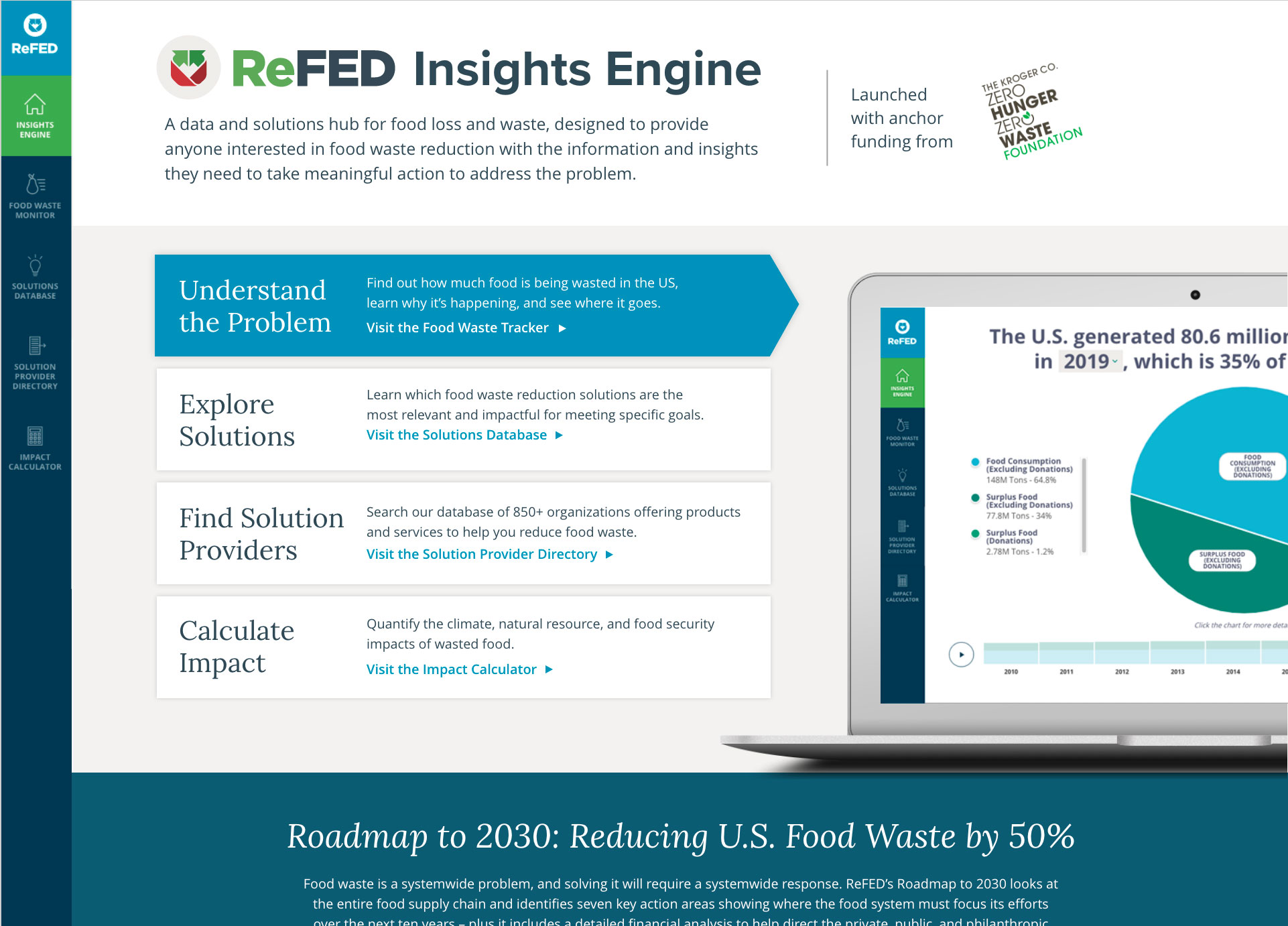

Your Source for Data and Solutions:

ReFED's Insights Engine

The Insights Engine is an online hub for data and insights about food waste built from dozens of public and proprietary datasets – plus estimates and information from academic studies, industry papers, case studies, and expert interviews – featuring a detailed financial analysis of more than 40 food waste reduction solutions; a directory of organizations ready to partner on food waste reduction initiatives; and more. With more granular data, more extensive analyses, more customized views, and the most up-to-date information, the Insights Engine can provide anyone interested in food waste reduction with the information they need to take meaningful action.

ReFED offers a range of solutions for organizations to advance their own food waste initiatives. Our interactive tools, reports and strategic solutions can help your team get started.